In a fast-changing textile environment, the use of PP spunbond nonwoven fabric has been like a breath of fresh air with a vast number of applications in different industries. Such a fabric, which is known for being light, long-lasting, and environmentally friendly, has captured the attention not only of the producers but also of the users. Thanks to its universal nature and affordability, it has become the most preferable material for medical supplies, agricultural covers, packaging, and even apparel. By figuring out the main characteristics, manufacturing processes, and trade aspects of PP spunbond nonwoven fabric, companies can use it as an industry of their own.

What Is PP Spunbond Non Woven Fabric?

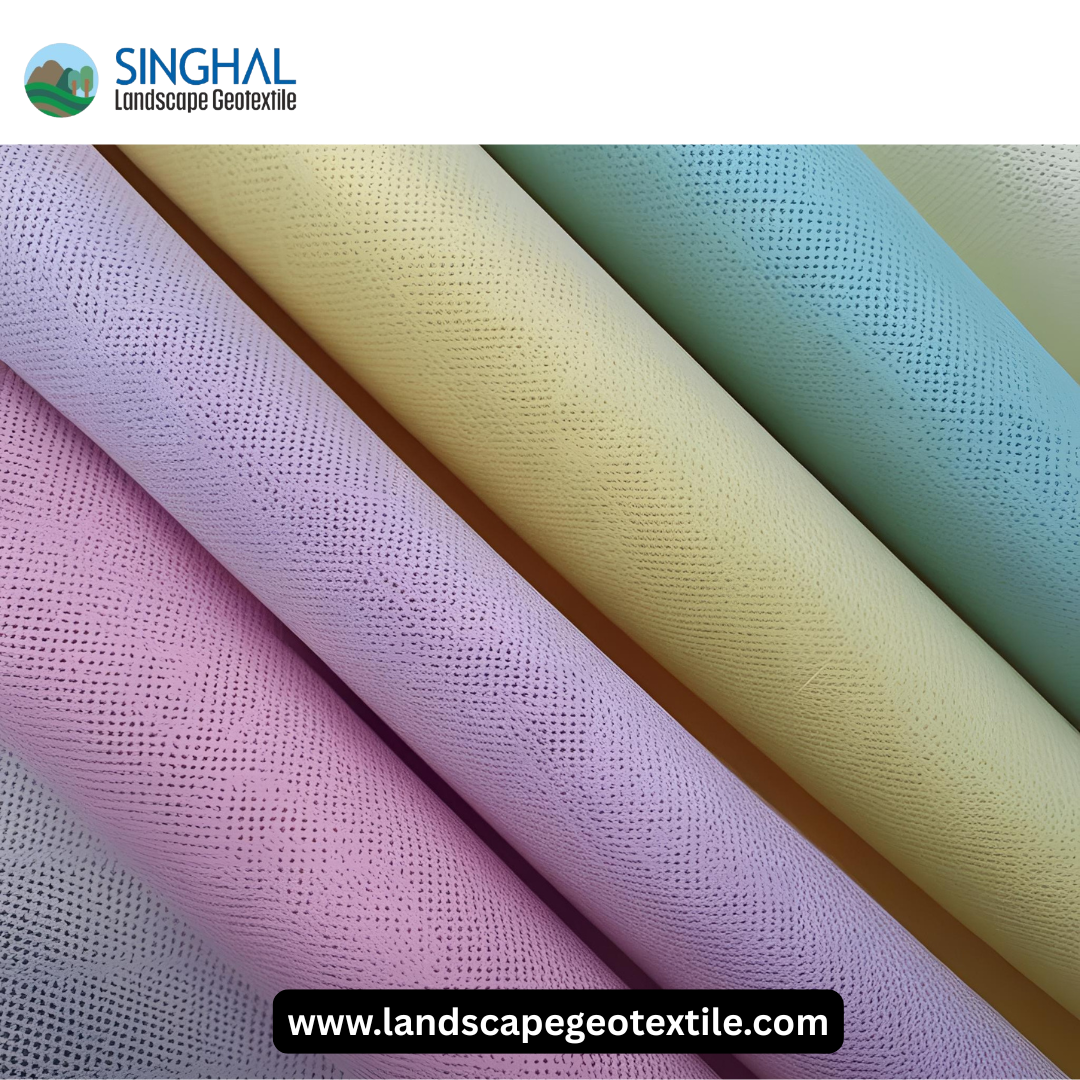

The PP spunbond non woven fabric manufacturer is a kind of fabric made from fibers of the plastic material polypropylene, that are bonded in the spunbond process. Woven or knitted fabrics are produced from the different methods but in this case, the material is a product of non-woven structures without weaving and thus making the fabric both more ventilated and more resistant to tear. In the process, polypropylene polymers are extruded into very thin filaments, which are laid into a web and bonded either mechanically, chemically, or thermally. In this method, the resulting fabric is not only very light but at the same time very strong and has a great resistance to adverse chemicals, UV rays, and general degradation by nature. The fabric finds its use in healthcare, agriculture, packaging, and hygiene products as its properties are unique.

Key Benefits and Applications of PP Spunbond Non Woven Fabric

The list of benefits was a major reason why the use of PP spunbond non woven fabric became very popular over the years. Since the fabric breathes, it allows both moisture and air to pass through and is therefore quite applicable to ventilated requirements. It is also very resistant to biological degradation, pests, and fungi, thus important in agricultural covers and medical disposable. Besides, the process of fabric manufacturing makes it possible to weigh, dye, and strengthen the fabric, which is a very good choice for different needs. In general, such materials are used for making surgical gowns, face masks, agricultural plastic films, shopping bags, geo-textiles, and even car interiors. The fact that it can be recycled and that it has a relatively low carbon footprint makes the fabric attractive in the current eco-friendly market.

The Role of a PP Spunbond Non Woven Fabric Manufacturer

A good manufacturer of PP spunbond nonwoven fabric is an important factor that determines quality, consistency, and availability of this multi-purpose fabric in the market. Such factories will employ state-of-the-art equipment and rigorous quality control methods to make products that comply with a set of specific standards required by various industries. Also, manufacturers change fabric requirements of customers in areas like weight, color, and width depending on what customers want. These companies also embrace the green concept by inventing eco-friendly substances and using recycled polypropylene to make the planet a safer place. Firms that work with a trusted manufacturer of PP spunbond nonwoven fabric will enjoy a lot of advantages like on-time delivery, price affordability, and access to the newest technology breakthroughs. It is worth mentioning that, for instance, Gujarat has been able to turn itself into one of the leading areas where these types of industries with its solid industrial base and educated labor force are located.

Understanding the Global Trade Aspects: PP Spunbond Non Woven Fabric HS Code

In simple words an understanding of the PP spunbond non woven fabric manufacturer in gujarat is the precondition for doing international trade of this product. Basically, the HS code stands for the Harmonized System code and it is a lean worldwide system for marking the goods we are trading. It normally associates a PP spunbond non woven fabric with the non-woven segment of the textile industry in the back category. Depending on what it is made of and how it is designed for, the non-woven fabric can be classified under chapter 56 or 63. With the correct categorization assigned it becomes easier for the customs officials to quickly clear goods with the right duties levied and also for the trade participants to abide by their respective import/export regulations. For the manufacturers and traders, it is imperative to be conversant with the exact HS code if they are to get a foot in the door of overseas markets and have smooth transactions across borders.

PP Spunbond Non Woven Fabric Manufacturer in Gujarat: A Growing Industry

Gujarat is the place where Indian industry has great potential and the state has turned itself into the main center of PP spunbond non woven fabric industry. The district advantage position, large capacity for handling the products through the sea, and enabling government regulations have been the main factors that have contributed to the influx of several manufacturers in the area. These firms churn out a wide variety of fabrics made from raw materials sourced locally but are fit for use not only in the domestic market but also in the foreign market. The well-trained labor force, cheap raw materials, and close distance between suppliers like the petrochemical complex and manufacturers are some of the benefits the Gujarat-based PP spunbond nonwoven fabric manufacturer enjoys. Apart from the local market, this dynamic industry is playing a big role in the global nonwoven fabric supply chain that in turn is helping India to make its mark in the international market.

Conclusion

The PP spunbond non woven fabric hs code is still changing the various parts of the world with the good mix of its power, and environmental safety. As the demand for eco-friendly materials grows, the manufacturers, especially those in the regions like Gujarat, play a vital role. The fabric has many uses as it can be easily adapted, from medical devices to biodegradable packaging materials. Any company willing to invest in this market should familiarize itself with the production process, trade classifications like the HS code, and the selection of reliable manufacturers and partners. PP spunbond nonwoven fabric is leading the way in the future of textiles as the demand for green and more functional materials rises.

Frequently Asked Questions

-

What is the main difference between spunbond and meltblown non woven fabrics?

Spunbond fabrics are more robust and thicker, generally used for long-lasting applications, whereas meltblown fabrics are very fine and are only used for filtration and medical masks. -

Is PP spunbond non woven fabric biodegradable?

Definitely, polypropylene is not biodegradable; nevertheless, it is recyclable and can be turned into new materials. -

What are common thicknesses or GSM (grams per square meter) for this fabric?

Normally GSM varies from 20 to 150 grams per square meter depending on the intended use of the fabric. -

Can PP spunbond non woven fabric be customized?

Indeed, in terms of color, width, weight, and even by adding additives for certain features, it can be customized. -

What industries mainly use PP spunbond non woven fabric?

The major sectors that have been using this fabric are healthcare, agriculture, packaging, automotive, and construction. -

Who is the largest supplier of PP Spunbond Non Woven Fabric?

All geotextile suppliers supply PP spunbond nonwoven fabric and other Geotextile Products. Singhal Landscape Geotextile are known to supply nonwoven fabric to landscaping. -

Who is the largest exporter of PP Spunbond Non Woven Fabric?

If Singhal Landscape Geotextile is an exporter of PP spunbond nonwoven fabric, they could be a major regional or niche supplier. -

Who is the largest manufacturers of PP Spunbond Non Woven Fabric?

The largest manufacturers of PP spunbond nonwoven fabric are several major Singhal Landscape Geotextile. -

Where can I find a reliable PP spunbond non woven fabric manufacturer?

Places like Gujarat are home to many good factories, and a lot of suppliers are going worldwide and can be reached via trade directories and industry expos. -

What should I consider when importing this fabric?

It's very important to have a clear HS code, and also quality certifications, good standing of the supplier, and that your country complies with import regulations.