Automation has become one of the most impactful developments in how products are made, distributed, and enjoyed — and the vaping world is no exception. Whether it’s improving device production, ensuring flavor consistency, or making online shopping smoother, automation continues to reshape the vaping experience. From brands like Beri Crush 50K, Mr Fog Vape, and Orion Bar Vape, the influence of automated systems can be seen in every stage of the process — from manufacturing to the moment a customer takes their first puff.

In this blog, we’ll explore how automation works behind the scenes, how it’s improving quality and safety in the vaping industry, and what it means for the future of vapers and manufacturers alike.

Understanding Automation in Vaping

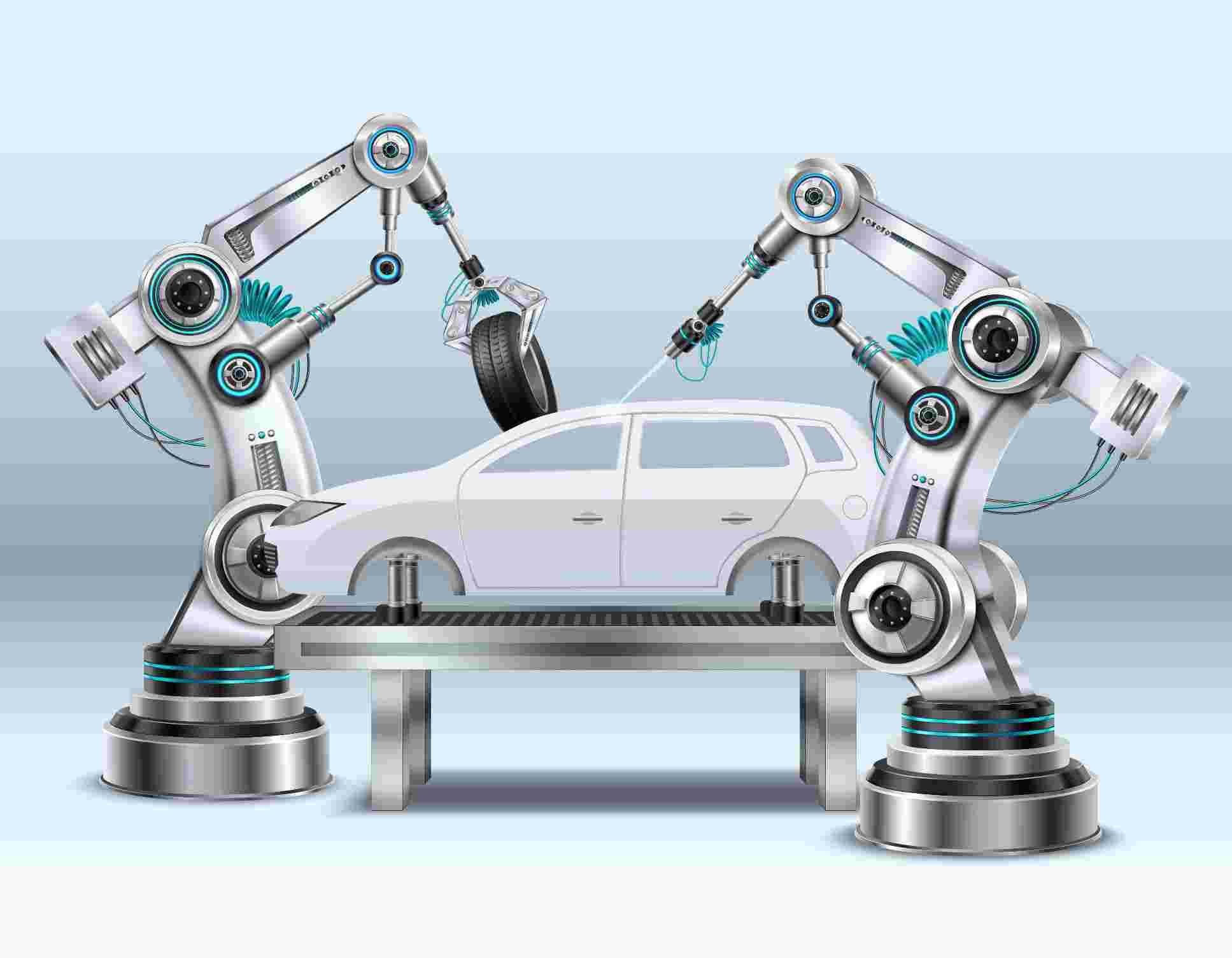

Automation refers to the use of technology and machinery to perform tasks with minimal human input. It’s not just about robots or computers — it’s about making systems more efficient, reliable, and consistent. In the vaping industry, automation helps streamline processes such as:

-

Device assembly – Automated machines can precisely assemble tiny components like coils, batteries, and sensors, ensuring each vape device meets safety and performance standards.

-

Flavor mixing – When producing e-liquids, automation helps maintain exact flavor ratios and nicotine strengths. This guarantees that each bottle of Beri Crush 50K or Mr Fog Vape offers the same taste experience every time.

-

Packaging and labeling – Automated systems reduce errors in packaging, helping brands keep their products compliant with labeling laws and ready for distribution.

-

Quality control – Automated quality testing checks for leaks, power output consistency, and battery safety — vital for maintaining user trust and brand reputation.

These steps not only speed up production but also make it possible for vape manufacturers to handle large-scale demand without compromising quality.

How Automation Improves the Vaping Experience

For many vapers, quality and reliability are the top priorities. Automation supports both. When production relies on human labor alone, minor mistakes can lead to inconsistencies — like uneven flavor strength or misassembled parts. Automated systems, however, use sensors and data monitoring to ensure uniformity and safety in every unit.

Here’s how automation enhances different aspects of vaping:

-

Flavor Accuracy – Automated e-liquid mixers are programmed to measure ingredients down to the milligram. This allows for accurate reproduction of complex blends like those found in Orion Bar Vape or Beri Crush 50K devices.

-

Device Reliability – Machines handle precision tasks, such as sealing cartridges and calibrating wattage levels, better than manual processes. This means fewer device malfunctions and a smoother vaping experience.

-

Safety Assurance – Automation also ensures compliance with global safety standards. Each Mr Fog Vape product, for example, must go through automated testing for battery performance and leak resistance before leaving the factory.

-

Efficiency and Cost – By speeding up production, automation reduces overall costs. This helps manufacturers keep prices stable, even as technology advances.

In essence, automation supports the balance between speed, precision, and safety — all crucial factors in maintaining trust among consumers.

The Role of Automation in Vaping Distribution and Customer Experience

Automation isn’t limited to manufacturing. It also plays a major role in how products are marketed, sold, and delivered to customers. Vape companies now use automated systems to improve logistics, online shopping experiences, and customer support.

Here are some key ways automation shapes distribution and interaction:

-

Inventory Management – Automated software tracks product availability in real time, preventing stock shortages and overproduction. This ensures that when someone searches for Beri Crush 50K or Orion Bar Vape, they find it in stock.

-

Personalized Marketing – Many online vape retailers use automated recommendation engines. These tools analyze user behavior and suggest products like Mr Fog Vape flavors based on past purchases or browsing habits.

-

Order Fulfillment – Modern warehouses use robotic systems to pick, pack, and ship products quickly. This reduces delivery times and improves customer satisfaction.

-

Customer Service – Automated chat systems handle basic inquiries 24/7, helping users find information about devices, flavors, or shipping without long wait times.

As e-commerce becomes more central to vaping, automation allows brands to maintain fast, accurate, and responsive service — which is now expected by customers worldwide.

The Future of Automation in the Vaping Industry

Looking ahead, automation will continue to evolve and influence how vaping products are made and enjoyed. While the current focus is on efficiency and safety, the next wave of automation could bring even more personalized and sustainable advancements.

Some key trends to watch:

-

Smart Manufacturing – Future factories will likely rely more on data-driven systems that can automatically adjust production settings for different flavors or device types. Imagine machines seamlessly switching between producing Beri Crush 50K pods and Mr Fog Vape disposables within the same hour.

-

Sustainability Integration – Automation can reduce waste by optimizing material use and recycling defective components. This supports eco-friendly goals many vape brands are starting to adopt.

-

Customization Options – Automated systems might allow customers to personalize nicotine strength or flavor intensity when ordering online. Brands like Orion Bar Vape could use automation to mix and produce customized pods on demand.

-

AI and Predictive Maintenance – Artificial intelligence could help detect potential production issues before they occur, minimizing downtime and preventing product defects.

These changes not only make production smarter but also align with consumer demand for safer, more personalized, and environmentally conscious vaping products.

Final Thoughts

Automation has quietly become one of the strongest forces behind the vaping industry’s growth. It ensures that each device — whether it’s a Beri Crush 50K, a Mr Fog Vape, or an Orion Bar Vape — is produced with precision, consistency, and safety. It also supports faster innovation, better distribution, and smoother customer experiences.

While vaping brands continue to compete in flavor, design, and technology, automation provides a foundation for reliability and quality. As technology advances further, it’s likely that automation will lead to even more efficient systems, safer products, and sustainable practices across the industry.

In short, automation isn’t just changing how vapes are made — it’s redefining what vapers can expect. It’s about making every puff consistent, every product dependable, and every experience better for those who enjoy vaping.